Food & Beverage

Enhancing Freshness, Safety, and Efficiency with Cryogenic Storage

In the food and beverage industry, product quality, hygiene, and process efficiency are critical. Our cryogenic storage tanks provide a reliable supply of food-grade gases like Liquid Nitrogen (LIN), Liquid Carbon Dioxide (LCO₂), and Liquid Oxygen (LOX), supporting a wide range of applications from production to packaging.

Applications in Food & Beverage:

-

Freezing & Chilling

Cryogenic freezing using liquid nitrogen enables ultra-fast freezing of meat, seafood, fruits, and ready-to-eat meals, preserving texture, flavor, and nutritional value.

-

Carbonation of Beverages

LCO₂ is essential for carbonating soft drinks, sparkling water, and beer. Our tanks ensure consistent gas quality and pressure for smooth, efficient beverage production.

-

Modified Atmosphere Packaging (MAP)

Using nitrogen and carbon dioxide to displace oxygen in packaging extends shelf life and maintains product freshness for baked goods, dairy, snacks, and more.

-

Cold Chain Logistics

Cryogenic gases help maintain controlled low temperatures during transport and storage, ensuring food safety from factory to shelf.

-

Inerting & Purging

Liquid nitrogen is used to remove oxygen from containers and tanks during processing, preventing oxidation and contamination.

Why Choose Our Tanks for Food Applications?

-

Food-Grade Compliance

– Manufactured to meet industry hygiene and gas purity standards.

-

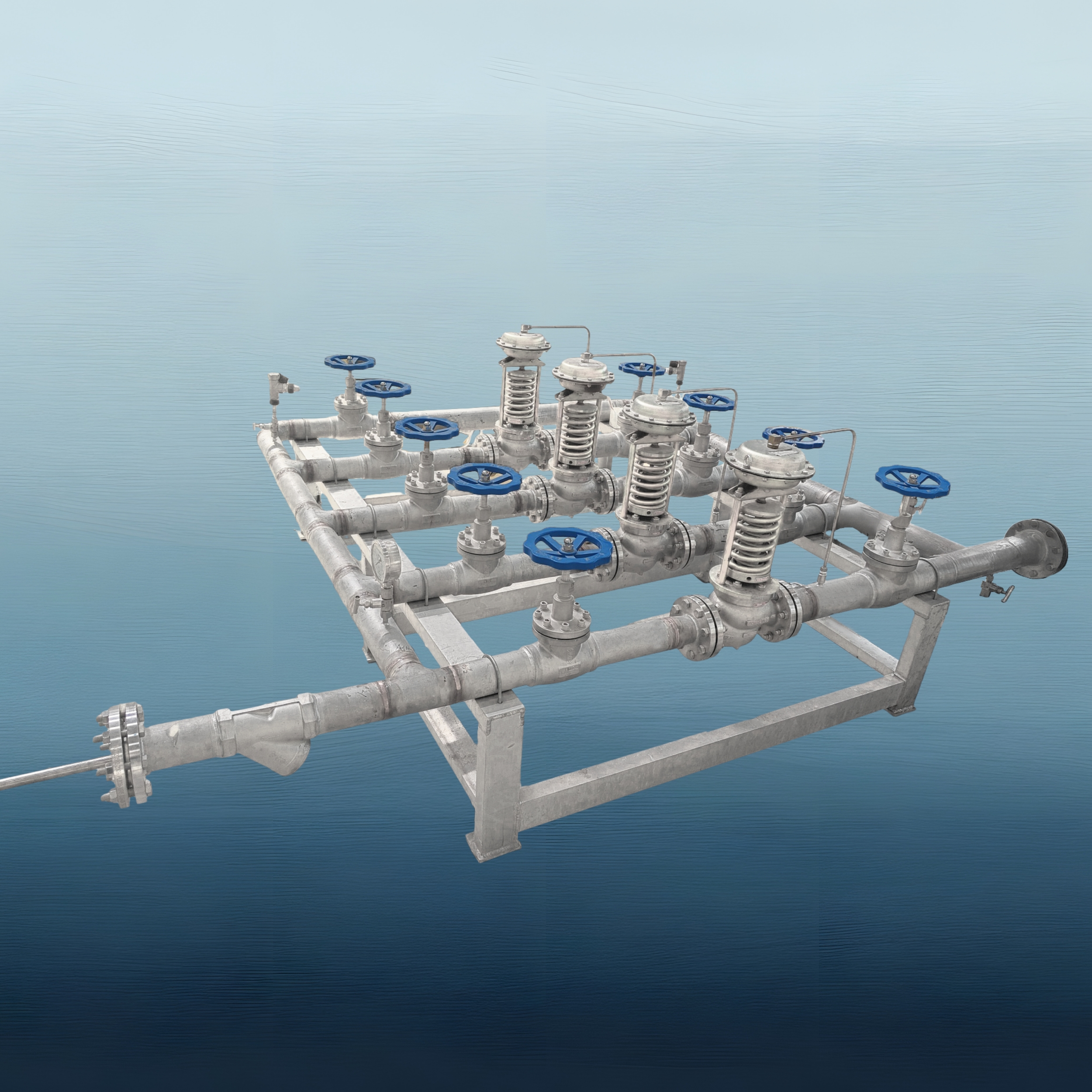

Precise Flow Control

– Supports automated production and packaging lines with reliable gas delivery.

-

Operational Efficiency

– Designed for minimal downtime and easy maintenance.

-

Safe & Hygienic Design

– Corrosion-resistant and easy-to-clean tanks for food environments.