Glass & Metals

Cryogenic Storage Solutions for High-Temperature, High-Precision Industries

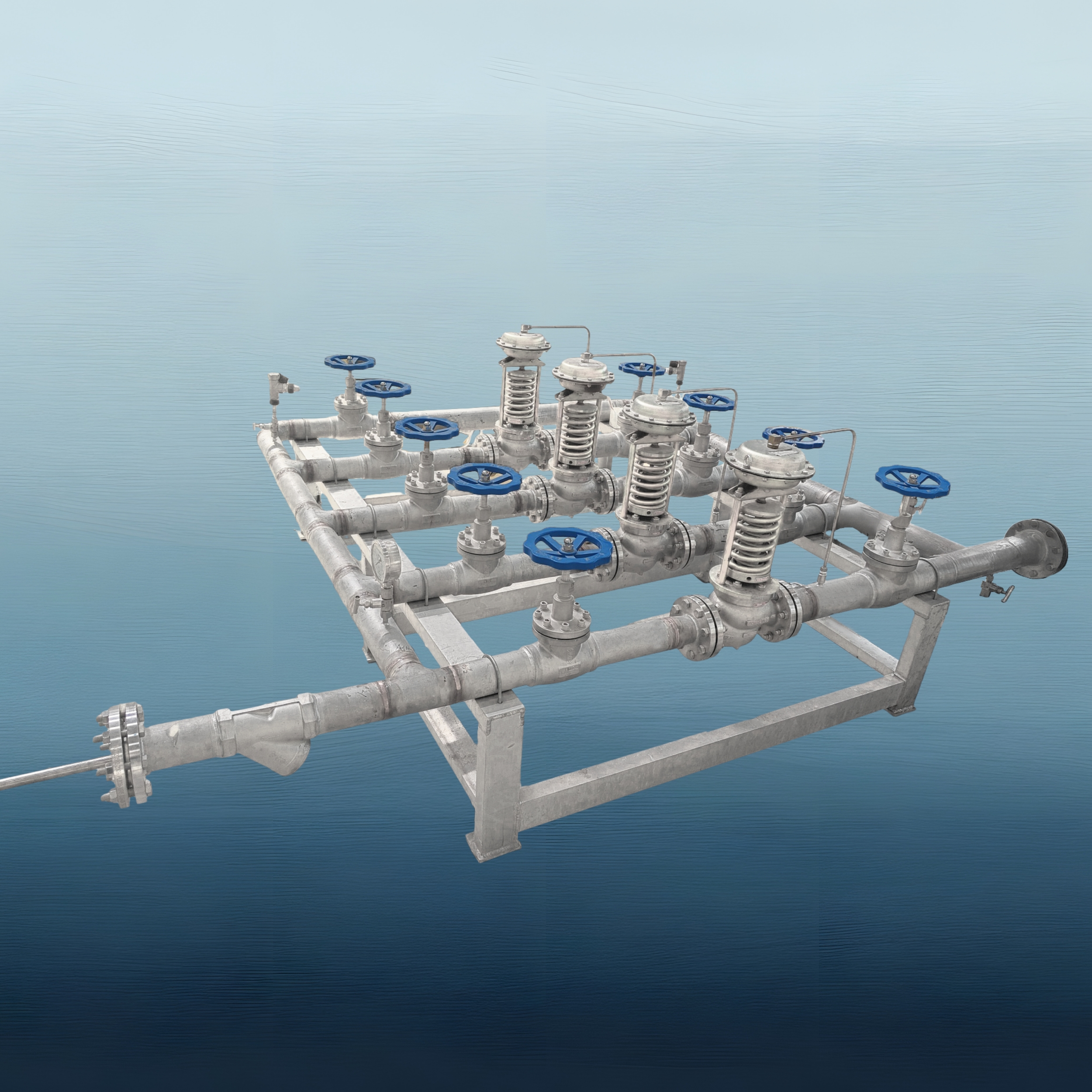

The glass and metals industries rely on consistent, high-purity industrial gases to enhance production quality, improve energy efficiency, and meet stringent process requirements. Our cryogenic storage tanks provide safe and stable storage for gases such as Liquid Oxygen (LOX), Liquid Nitrogen (LIN), and Liquid Argon (LAR), which are widely used in furnace operations, metal fabrication, and thermal processing.

Applications in Glass & Metals:

-

Glass Manufacturing

Liquid oxygen is used to boost combustion efficiency in glass melting furnaces, resulting in higher flame temperatures, lower fuel consumption, and reduced emissions.

-

Float Glass & Container Glass

Oxygen enrichment enhances flame temperature and stability, improving glass clarity, uniformity, and production speed.

-

Steel & Iron Production

Oxygen is critical in basic oxygen furnaces (BOF) for decarburization and increasing furnace efficiency. Our tanks ensure a reliable gas supply to maintain consistent steel quality.

-

Aluminum and Non-Ferrous Metal Processing

Cryogenic gases assist in degassing, refining, and inerting during smelting and casting processes, preventing oxidation and improving metal purity.

-

Welding, Cutting & Heat Treatment

Oxygen, argon, and nitrogen are used in various thermal operations, such as plasma cutting, arc welding, and surface hardening. Our tanks support stable flow for precision work.

Why Choose Our Tanks for Glass & Metals?

-

High Durability

– Engineered to perform under demanding, high-temperature plant conditions.

-

Continuous Supply Assurance

– Ideal for 24/7 furnace and foundry operations.

-

Customizable Capacities

– Tailored to fit small workshops or large-scale production lines.

-

Gas Purity Control

– Maintains consistent gas quality for metallurgical and optical-grade outputs.